Technical data sheet composition Materials:

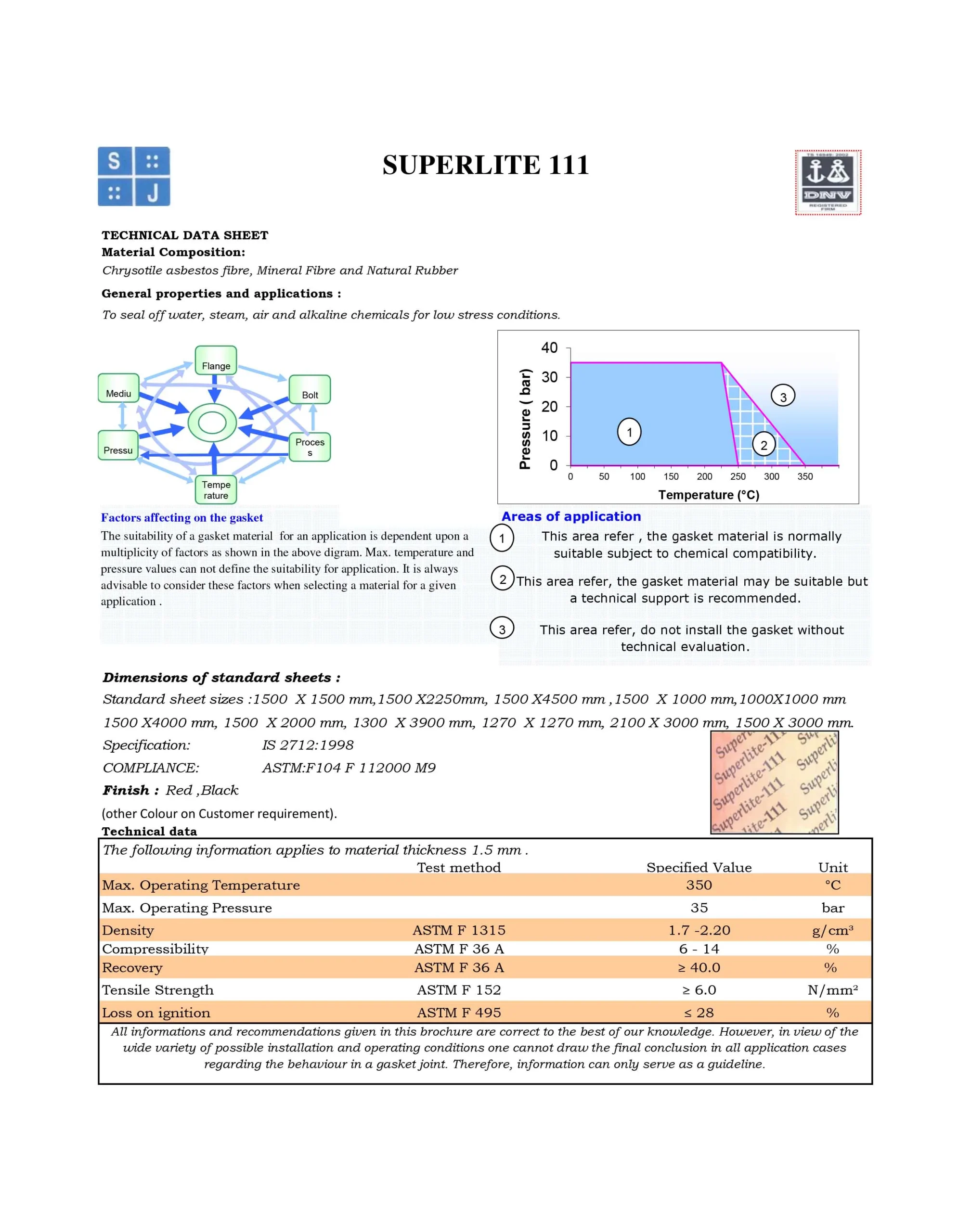

Factors affecting gasket

SUPERLITE “PLUS” 3000

Asbestos Chrysotile fibers, mineral fibers, natural rubber

General properties and applications: For sealing water, steam, air and alkaline chemicals for low pressure conditions.

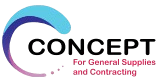

Areas of application

The suitability of a gasket material for an application depends on a large number of factors as shown in the digram above. Max. temperature and pressure values cannot determine suitability for an application. It is always advisable to consider these factors when

This area indicates that the gasket material is normally suitable for chemical compatibility.

This area indicates that the gasket material may be suitable but

Standard sheet dimensions:

1500 x 4000 mm, 1500 x 2000 mm, 1300 x 3900 mm, 1270 x 1270 mm, 2100 x 3000 mm, 1500 x 3000 mm.

Specifications: IS 2712:1998 Compliance: ASTM: F104 F 112000 M9 Finish: Grey / Graphics (Other colors as per customer requirement).

Technical Information

The following information applies to material thickness 1.5 mm. Test Method Specified Value Unit Max. Operating Temperature 320

Max. Operating Pressure 30

Density ASTM F 1315 1.7 -2.20 Compression ASTM F 36 A 6 – 14 Recovery ASTM F 36 A ≥ 35.0 Tensile Strength ASTM F 152 ≥ 6.0 Loss on Ignition ASTM F 495 ≤ 25.0

°C

Application. It is always advisable to consider these factors when selecting a material for a particular application.

This area indicates that gasket materials may be suitable but technical support is recommended.

This area indicates, Do not install gasket without technical evaluation.

Standard sheet sizes: 1500×1500 mm, 1500×2250 mm, 1500×4500 mm, 1500×1000 mm, 1000X1000 mm

All information and recommendations given in this manual are correct to the best of our knowledge. However, in view of the wide range of possible installation and operating conditions one cannot draw a final conclusion in all cases of application regarding the behavior in a joint gasket. Therefore, the information can only serve as a guide.